- Inicio

- fortify board

- Water Cooling Channels Decrease 3D Printed Mold Tool's Cycle Time by 50% - Fortify

Water Cooling Channels Decrease 3D Printed Mold Tool's Cycle Time by 50% - Fortify

4.6 (334) · € 7.00 · En stock

Fortify and PTC worked together to prove out if water cooling channels designed into the 3D printed mold tool could help reduce cycle time.

Current Status in the Utilization of Biobased Polymers for 3D Printing Process: A Systematic Review of the Materials, Processes, and Challenges

Polymers, Free Full-Text

Do Water Cooling Channels Decrease Cycle Time for 3D Printed Mold Tools?

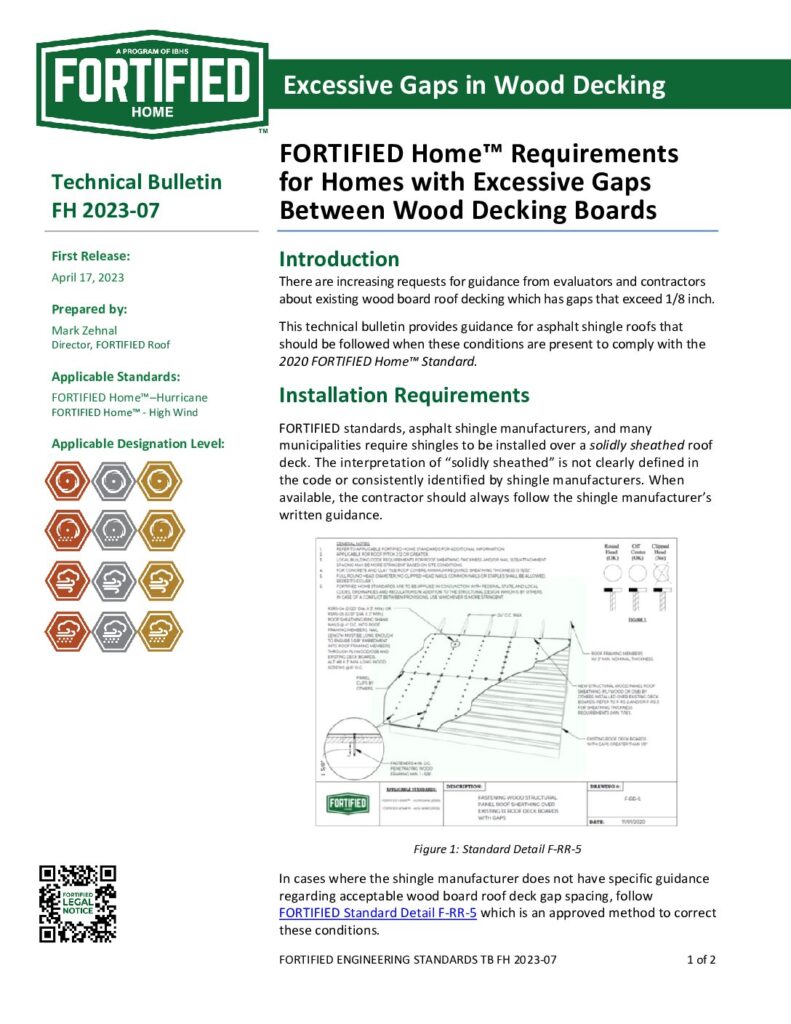

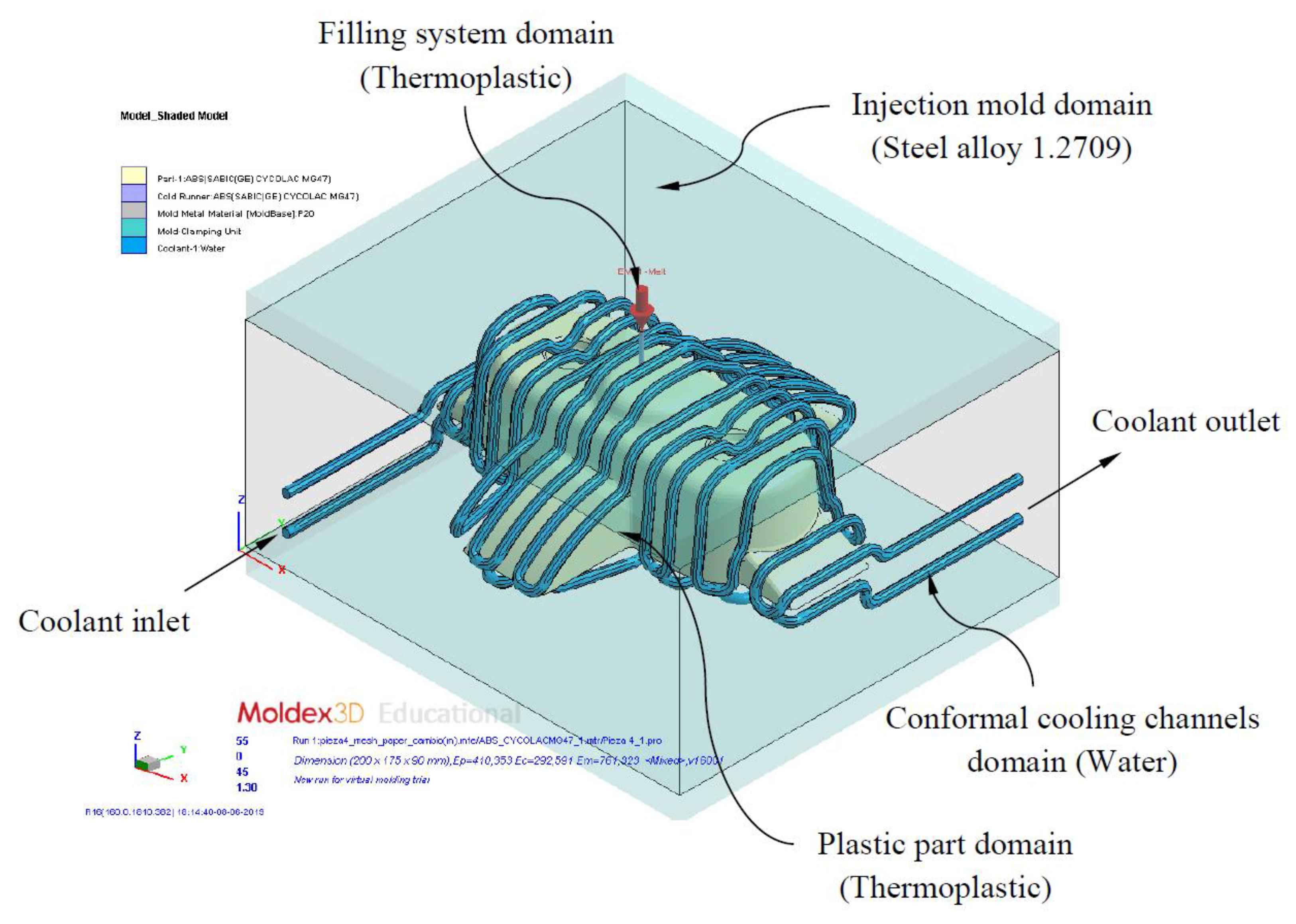

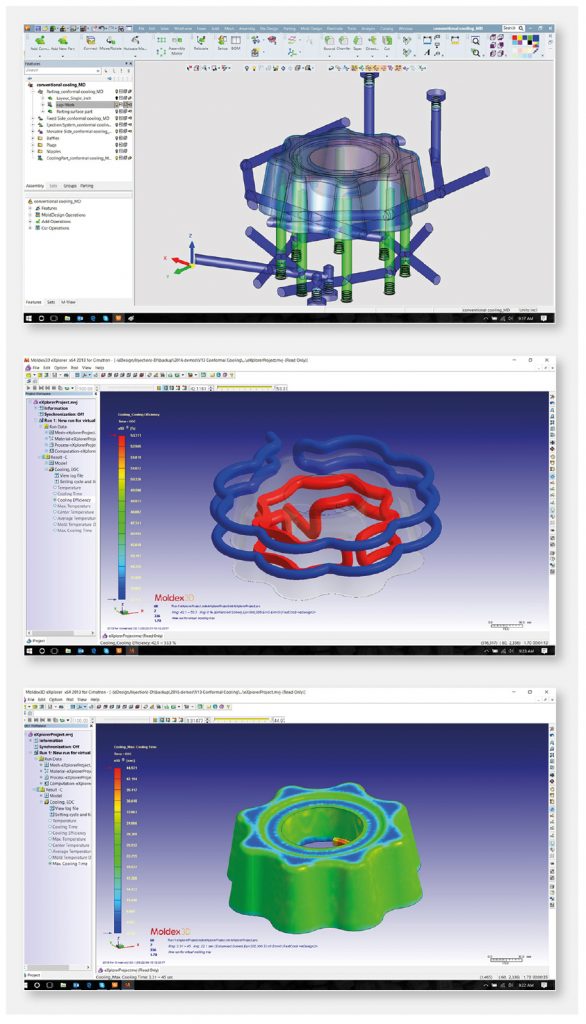

Development of green conformal cooling channels for rapid tooling

Benjamin MacDonald on LinkedIn: #additivemanufacturing #injectionmolding

Current Status in the Utilization of Biobased Polymers for 3D Printing Process: A Systematic Review of the Materials, Processes, and Challenges

Reshaping the Mold: How Metal 3D Printing Can Improve Tooling - Velo3D

Conformal cooling: How Additive Manufacturing benefits injection moulding

Development of green conformal cooling channels for rapid tooling

Digital Tooling Cooling Channels

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

Metal 3D Printed Conformally-Cooled Injection Mold Increases Production Rate by 30% - Miller 3D